Buy Saskatchewan Manitoba cutting edges blades carbide grader teeth heat treated high carbon bucket loader excavator tips sales scraper blade price quote sale

ValliteTM - Hot rolled alloy steel, heat treated and stress relieved for unmatched thru-hardness and impact strength.

High Carbon - Hot rolled steel profile with high carbon content.

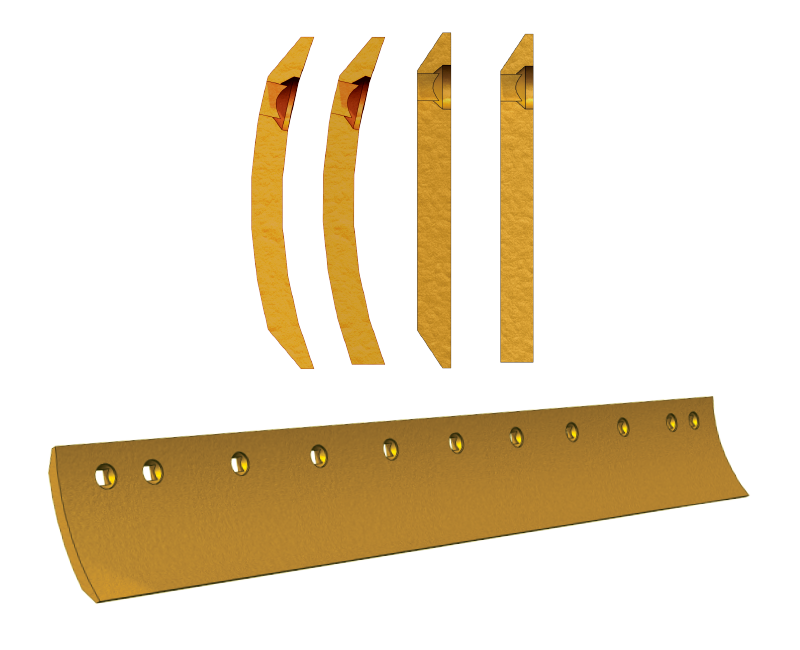

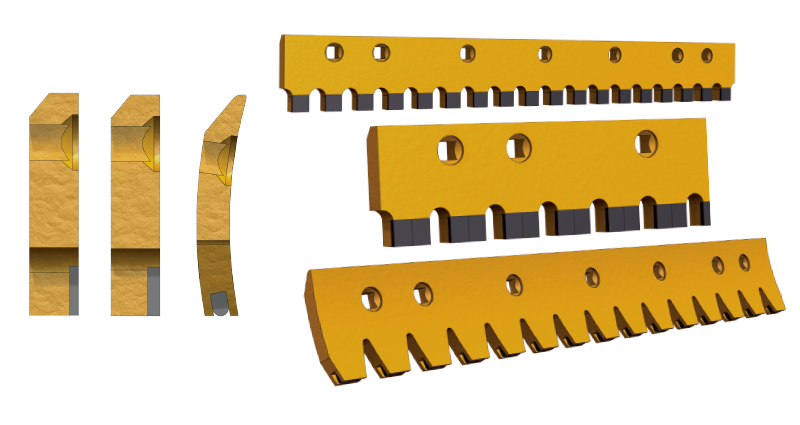

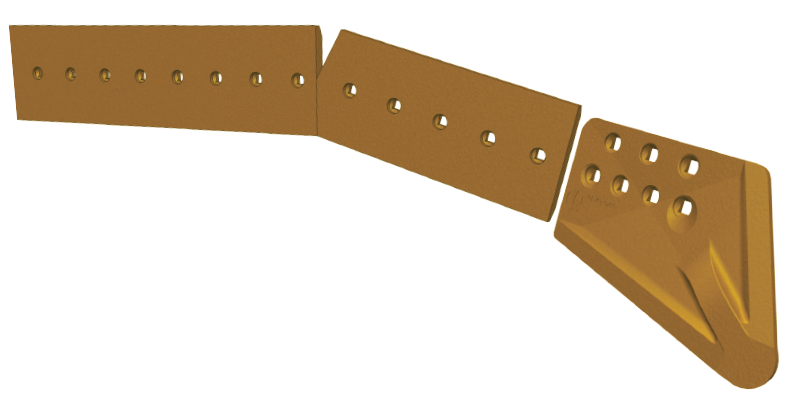

Standard grader blades are available in various sizes of flat and curved

profiles in single or double bevel, with hole sizes and patterns to suit all

OEM equipment.

From the free cutting “sharp” 1/2” X 6” curved to the massive 3” X 16” flat.

Curved: (1/2” X 6”) to (1” X 8”) Flat: (5/8” X 6”) to (3” X 16”)

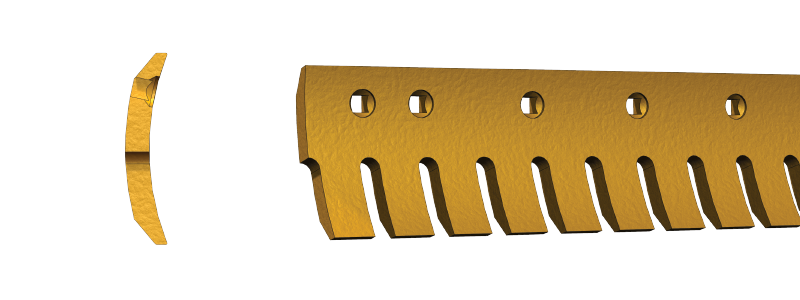

Scarify frozen or hard packed roads with VBLTM Serrated or “Sawtooth” Grader Blades.

ValliteTM - Hot rolled boron alloy steel, heat treated and stress relieved for unmatched thru-hardness and impact strength.

High Carbon - Hot rolled steel profile with high carbon content.

Valley Blades Ltd began operations in 1962 as a

small manufacturing facility in Cambridge Ontario.

In 1976 the original Cambridge manufacturing facility was

closed and the company moved its headquarters to

Waterloo, Ontario, Canada, where the plant sits today.

In 1977 Valley Blades Ltd. expanded its facilities

and its market by building a 15,000 square foot

manufacturing plant in Edmonton, Alberta, Canada.

This facility has since grown to become an integral part of Valley Blade's

manufacturing and Distribution System.

Today Valley Blades Ltd manufactures high quality cutting edges

and snow plow blades for any OEM machine servicing

the municipal, construction and heavy machinery markets.

The Waterloo plant currently occupies in excess of 65,000 square feet

of manufacturing and warehousing space.

CNC cut “teeth” are available as an option on any standard curved or flat grader blade, with hole sizes and patterns to suit all OEM equipment. Various “tooth” profiles are available to suit any application.

*Custom size configurations available on request

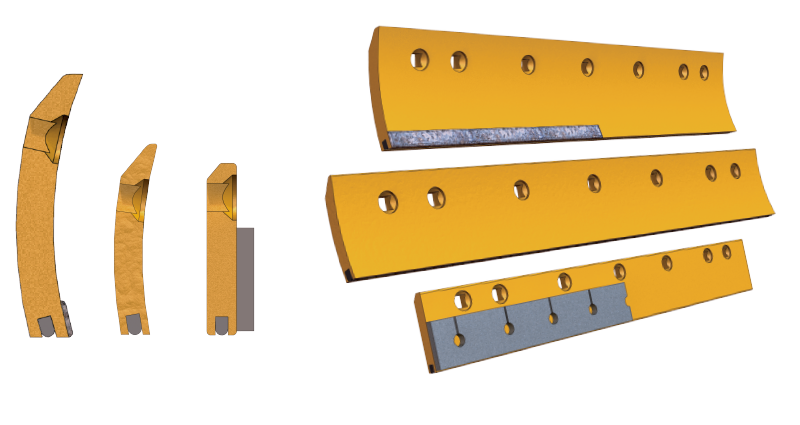

For extra long life in abrasive conditions or plowing snow, choose VBLTM Carbide Tipped Grader Blades.

Tungsten carbide inserts brazed into a specially prepared groove in the

blade will increase wear life several times when compared to conventional blades. This makes carbide tipped grader blades ideal for severe wear applications. Various sizes and shapes of tungsten carbide inserts are available to suit any application.

VBL applied tungsten carbide matrix (TCMTM), hard facing or strips of hardened plate (VALSTRIPTM) are available as options to prevent premature base material wear “washout”. Carbide tipped grader blades are available in various sizes of flat and curved profiles, with hole sizes and patterns to suit all OEM equipment.

*Custom size configurations available on request

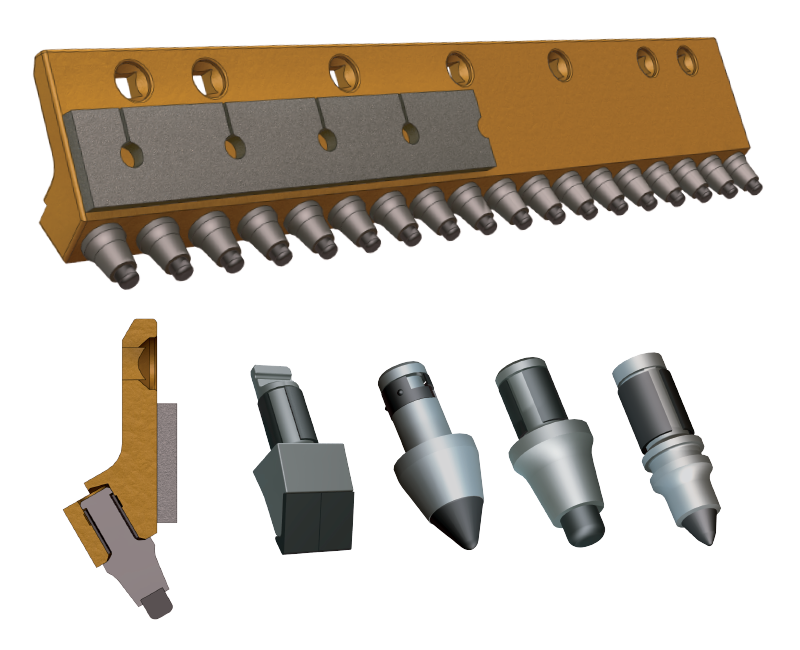

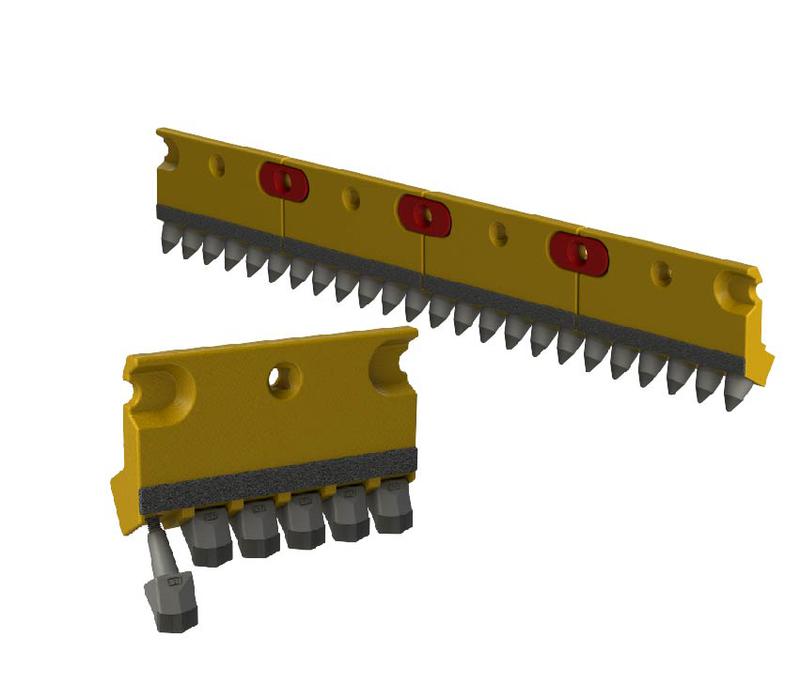

In extreme scarifying applications, VBLTM CARBITTM Blades and Tips are the clear choice.

VALLITETM heat treated (thru-hardened) blades with replaceable carbide tips offer the best performance for scarifying roads. A variety of rotating and fixed (non-rotating) tips are available to tailor this product to any application. The CARBITTM system is available in different sizes to suit all sizes of OEM machines.

VBL applied tungsten carbide matrix (TCMTM), hard facing or strips of hardened plate (VALSTRIP TM) are available as options to prevent premature base material wear “washout”.

In frozen road scarifying or "Ice Blading" applications choose VBLTM Serrated Carbide Tipped Grader Blades for long wear life.

Tungsten carbide inserts brazed into specially prepared areas in the blade will increase wear life several times when compared to conventional blades.

This makes serrated carbide tipped grader blades ideal for severe wear applications.

Various sizes and configurations of tungsten carbide inserts are available to suit any application.

Serrated carbide tipped grader blades are available in various sizes of flat and curved profiles, with hole sizes and patterns to suit all OEM equipment.

*Custom size configurations available on request

All logos and content in this site are property of their respective owners

For Brochures and Literature on Cutting Edges Please Visit

our BROCHURS/PARTS BOOKS Page.

VBL™ self-sharpening side pin teeth are a great choice for any bucket requiring high-performance wear parts.

Using computer models and wear simulations VBL™ side pin teeth have been engineered with high performance, self-sharpening features on all shapes and sizes.

(L) Long — Good combination of wear life and penetration. Basic choice for loaders or excavators.

(RP) Rock Penetrator — A penetration shape plus an engineered wear pad on the bottom make an excellent design for front-end loaders.

(F) Flare — Wide, flat profile leaves a flat floor as well as extends bucket capacity. Great choice for excavators in loose material.

(T) Tiger — Sharpest tooth available for high penetration in hard-packed materials.

(TT) Twin Tiger — Double version of tiger primarily used on the ends of the bucket to cut clearance.

(RC) Rock Chisel — Best choice for heavy impact in rock, will penetrate well and pry rocks loose.

When safety and performance are critical choose VBL™ locking, sectional, forged, heat-treated CARBIT™ system. CARBIT LINK™.

Safety: 30lb (12.5kg), 12” (305mm) segments are safe and easy for one person to handle, helping to reduce injury. The sectional design also makes storage easier for applications where scarifying is only done at certain times of the year.

Rigidity: Locking sectional design eliminates joints between blades making for a more rigid installation.

Wear: Segments and locks are forged and heat treated for strength. Tungsten Carbide Matrix (TCM) wear protection comes as standard for the best possible wear life.

Bits*: The VBL™ TAPER-LOCK™ tool brings non-rotating bits to the next level with an extremely secure mounting system that ensures easy removal of bits even after years of use.

*Also available with a full range of standard 7/8” (22mm) rotating and non-rotating bits.

VBL heat treated parts are warranted against breakage throughout the useable life of the part.

Yorkton Saskatchewan Manitoba Degelman Mower Culvert Landa Cutting Edge Blade Teeth Used HDPE Plastic Schulte Bushhog REV 1500 Side Arm pressure washer drainage tile weeping tile sale buy sell used carbide parts book packer CAT grader parts

Culvert HDPE Plastic Pipe Culvert Yorkton Saskatchewan Canada Manitoba Sale Sell Buy galvanized culvert CSA C.S.A. Smooth wall plastic

Yorkton Saskatchewan Manitoba Degelman Mower Culvert Landa Cutting Edge Blade Teeth Used HDPE Plastic Schulte Bushhog REV 1500 Side Arm pressure washer drainage tile weeping tile sale buy sell used carbide parts book packer CAT grader parts

Call: 306 782 4055